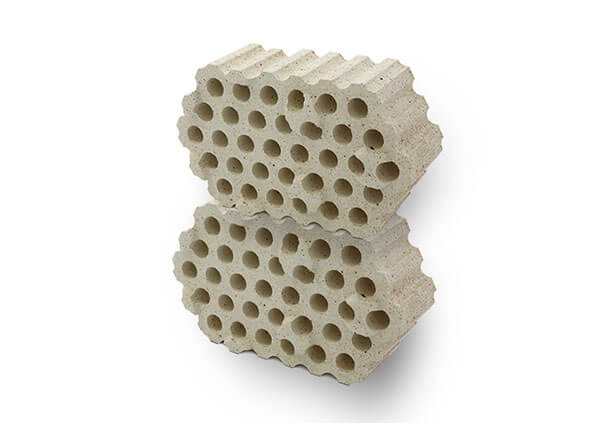

The silica brick for hot blast stove is used to build the silicon refractory products with scaly quartz as the main crystal phase in the high temperature part of the blast furnace hot blast stove.

The silica brick for hot blast stove is used to build the silicon refractory products with scaly quartz as the main crystal phase in the high temperature part of the blast furnace hot blast stove. The hot air temperature of the blast furnace increased from 500-650℃ in the 1940s to 1000℃ in the 1970s, and the hot air of the large blast furnace in the 1980s has been increased to 1350℃. Due to the increase in wind temperature, clay bricks or high-alumina bricks used in the high-temperature parts of previous hot-blast stoves have been gradually replaced by silica bricks and low-creep high-alumina bricks.

| Item | Common Si Brick | Si Brick for Hot-blast Furnace | |||

| GZ--95 | GZ--94 | GZ--93 | Arch Top Brick | Checker Brick | |

| SiO2 | ≤95% | ≤94% | ≤93% | ≤95% | ≤95% |

| Refractory | ≥1710℃ | ≥1710℃ | ≥1690℃ | - | - |

| RUL(0.2Mpa) | ≥1650℃ | ≥1640--1620℃ Bonded Si Brick | ≥1620℃ | - | - |

| AP | ≤22% | ≤23% | ≤25% | ≤22% | ≤23% |

| CCS | ≤29.4Mpa | ≤24.5Mpa | ≤19.6Mpa | ≤35Mpa | ≤30Mpa |

| True Density | ≤2.33g/cm3 | ≤2.37g/cm3 | ≤2.39g/cm3 | ≤2.35--2.34g/cm3 | |

| High Temp. Creep Rate (0.2Mpa 1550℃ 5h) | - | - | - | ≤0.8% | |

| Thermal Expansion (1000℃) | - | - | - | ≤1.26% | |

If you are interested in our products, please leave your contact information and products, we will reply you in time.